Ultra-fine grinding

Product size some µm to some hundreds nm

Jet Mill

Spiral Jet Mill AS

- Simple structure without rotating parts.

- Unique grinding mechanism, which prevents coarse materials from entering the product.

- Ability to grind low-melting point materials to a few μm.

- Corresponds to GMP standards for easy disassembly and CIP/SIP.

Jet Mill

Alpine Microbust AMB

- Ultra-fine grinding of coarse and fibrous materials without preliminary crushing

- Large, central material infeed from top to bottom

- Grinding chamber can be flexibly adapted to the properties of the material to be ground

- Fast cleaning and straightforward disassembly thanks to clamp fittings

- Modular machine design and simple Ex concept

- High wear protection due to ceramic components (optional)

- Also available in stand-alone baseline version

Jet Mill

Fluidized Bed Opposed Jet Mills AFG, AFG-R,AFG-CR

- Sharp classifying performance.

- For materials of any hardness.

- Low product contamination.

- Simple construction.

- Low noise emission.

- Almost 1,000 references for an enormous variety of application.

Jet Mill

Fluidized Bed Opposed Jet Mills AFG-CR

- CR ultra fine classifier is integrated in AFG for milling down below one micron.

- The classifying wheel is designed on basis of the forced and the semi-free vortex theory, resulting in sub-micron classification.

- Combining with opposed jet mill technology,

- Ceramics classifying wheel for metal free product is available.

- Scale-up with multi-wheel classifier.

Jet Mill

Fluidized Bed Opposed Jet Mills TFG

- High precision of cut.

- Suitable for toner grinding.

- Good accessibility for cleaning to minimize the downtime during a color change.

- A hydraulic mechanism permits the classifier head to be raised and then swung off to the side through 180°.

Jet Mill

Fluidized Bed Opposed Jet Mills TTG

- TTG jet mill is equipped with a Turbo-Twin classifier head that substantially reduces the pressure drop of the classification.

- Produce sub-micron particles at high capacity.

- Application areas:

- Mineral powders, Graphite, Mineral fillers. Talc, Barium sulphate, etc.

Jet Mill

Micron Jet-T MJT

- Target(impact) type jet mill.

- High grinding efficiency.

- Easy adjustment of product size.

- Highly precise classification possible as ground particles enter the classifying zone in highly dispersed conditions.

- Easy Cleaning.

Jet Mill

Micron Jet-Q MJQ

- Target(impact) type jet mill.

- High energy efficiency.

- Low residue in the mill.

- Very-easy-to-clean construction.

- Easy size control.

- Designed for handling sticky materials.

- All-ceramics construction is possible.

- Applicable for neodymium iron boron for magnet.

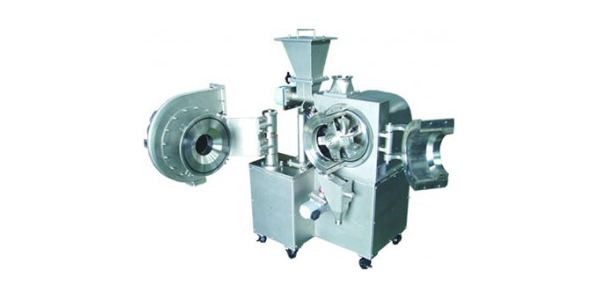

Attrition Type Ultra Fine Mill

Super Micron Mill MEC,M

- Grinding mechanism that utilizes the 3 largest grinding principles. (Impact, Shearing, Attrition)

- Space saving: 65% more compact compared to past models. (Compared as a whole system)

- Low Noise level : under 85dB.

- Equipped with contaminant separation mechanism.

- The Super Micron Mill M model uses the same attrition grinding mechanism as the renewed MEC model.

Impact Type Ultra Fine Grinding Mill

Innomizer INM

- High grinding capabilities.

For example, in the case of grinding toner, 30-50% cost reduction (comparing energy consumption ratio) can be expected relative to conventional jet mills. - For high grade, high added value of products.

- Easy particle size control.

- Easy Maintenance and Inspection.

- Wide variety of designs.

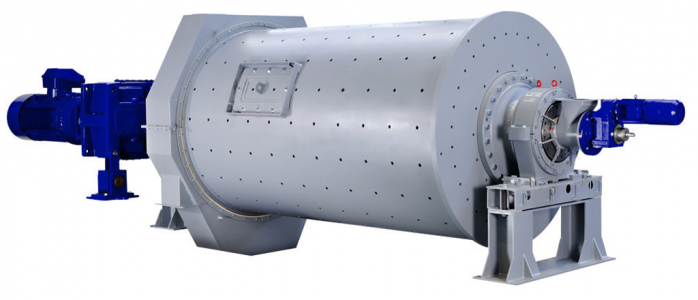

Agitating Media Mill

Super Orion Ball Mill S.O.

- Cast side plates bolted to a welded grinding drum.

- Integrated manhole.

- Drive via ring and pinion gear with automatically controlled tooth lubrication, back gearing with couplings and high-performance gear unit.

- Product discharge via adjustable slots located around the periphery of the drum. Two part discharge housing with top venting connection and inspection cover.

- Bearing unit: grease-lubricated anti-friction bearings, central lubrication system. Friction bearings also possible if required with permanent oil-re-circulation lubrication and temperature control.

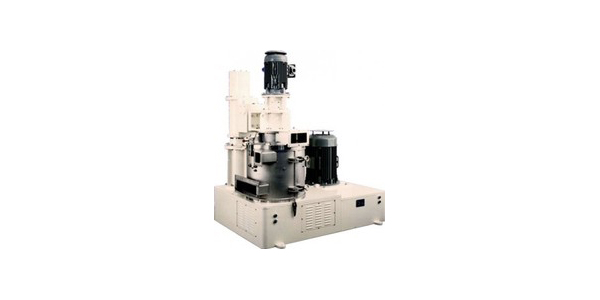

Agitating Media Mill with an Integrated Classifier

Pulvis PV

- Energy efficient compared to jet mill.

- Possible to grind down to ultra fine particles (sub-micron).

- Easy particle size adjustment.

- Ceramics construction possible for powder contact part.

Wet Process Agitated Ball Mill

Vertical mill ANR

- Open-design vertical agitated media mill for single-pass mode

Suitable for superfine calcium carbonate and other mineral powder slurries

Suitable for continuous operation

Low maintenance machine - Ceramic wear protection ensures high degree of whiteness

- Cost effective due to low grinding energy requirement

Wet Process Agitated Ball Mill

Hydro-Mill AHM

- Easy Dis-assembly and Cleaning.

- The mill is equipped with either a stationary or mobile support unit that guarantees a simple disassemble procedure for cleaning and maintenance.

- Wear protection.

- For the application which require special c are for metal contamination, the agitator disc and liner pipe can be coated with either high-grade ceramics or tungsten carbide. A mono-block ceramics structure is possible as well.

Table Roller Mill + new integrated ACP Classifier

AWM-F

- Energy saving against ball mill / classifier process

- No use of grinding aid

- Investment saving due to compact design

- Fineness up to D97 = 8 micron