CLASSIFYING

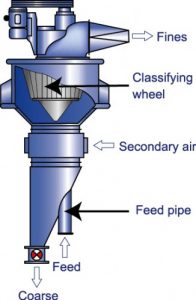

Centrifugal Force Classifier

Micron Separator MS

- The classification range is wide and is suitable for a wide variety of applications. (Dth=3 – 150μm is possible)

- No sealing air is required, this allows for a low energy consumption and simpler ancillary equipment.

- The wheel blades are very robust and exchangeable replaced. Wear protection is also available.

- The classification size can be easily controlled by changing the speed of the wheel.

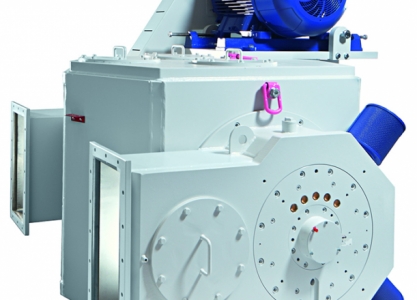

Centrifugal Force Classifier

Turboplex Classifier ATP

- Horizontal classifying wheel.

- Robust design.

- Ultrahigh fineness values.

- Sharp top-size limitation.

- Stable operation even at fluctuating feed rates.

- Universal in use.

- Sophisticated technology.

- Easy classifying wheel exchange.

- Low maintenance costs.

- Multi rotor design enables fine cut point in scale-up models.

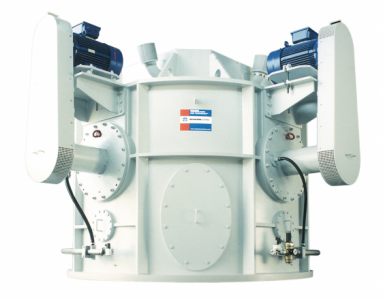

Centrifugal Force Classifier

Turbo Twin Double Classifier TTD

- Low energy costs as well as low investment costs per ton of end product.

- High fines yield and maximum fines capacity.

- Extremely robust and durable construction.

- Classifying wheel supported in bearings on both sides.

- Dual-flow fines discharge.

- Optimized product feed direct to classifying wheel.

- Direct drive with reinforced motor bearing.

Centrifugal Force Classifier

Toner Classifiers TSP

- Developed especially for dedusting toner.

- Superior ultra-fines removal performance.

- Counter flow classification realizes the high yield and capacity.

- No back-mixing by deliberate product routing design.

- Optimum access for quick and thorough cleaning at minimum downtime.

Inertia Force Classifier

Cliffis CF

- High classifying efficiency.

- For the top cleaning of toner, it gives very high classifying efficiency.

- Way-out Design.

- It doesn’t require a Coanda wall and simplify the internal structure.

- Easy maintenance.

- Quick and easy disassembling/cleaning procedure due to no moving parts and smooth interior design.

Zig Zag Classifier

MZM and MZF Multi-Plex

- Two different designs: MZM and MZF.

- Each design is available in a range of machine sizes from a single-tube to a multi-tube classifier.

- Ideal for sharp separations in the range d97 = approx. 0.3 – 10 mm.

- Throughput can range from a few kg/h in the case of the laboratory classifier up to approx. 200 t/h for the industrial-scale multi-tube classifier.

- Classification takes place at every change in direction of the zigzag tube and permits an extremely high, steplessly adjustable precision of cut. The result is clean-cut fines or lightweight material, even under overload conditions.