Crop Protection Agents

as powder, granules or extruded material

The number of people who have to be fed from one hectare of agricultural land has increased drastically over the past decades. Agrochemicals are becoming increasingly important in the efforts to feed growing global population.

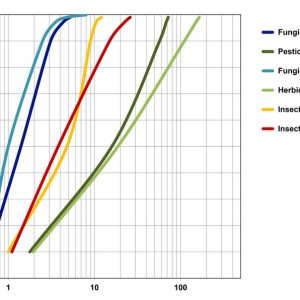

Suitable process solutions and individual components matched to each other are indispensable for the production of plants protectors (fungicides, herbicides, pesticides) with small particle sizes and dispersible granule shape.

Besides the demands on the product itself, a host of other requirements need to be considered:

- Explosion-protected systems as defined in ATEX directives

- Optimum process control and automation

- Containment solutions for personnel protection

- Easy and effective cleaning up to fully automated CIP solutions

- Wear protection for abrasive materials

- Special solutions for sticky products

Because many plant protectors exhibit both toxic and also explosive properties, we make sure that our processing equipment fulfils every requirement to do with operator protection, handling, storage and environmental protection.

Thanks to the wide product range available within the Hosokawa Group, the core processes such as drying, grinding, classifying, mixing, agglomeration or extrusion can be perfectly matched to each other and supplied from one single source – independent of the particle size or targeted throughput. In this way, flexible systems can be configured which do justice to the sometimes critical products common in the agricultural industry.

Solutions

Drying

- Required capacity

- Feed – slurry, paste, filter cake

- Required end moisture

- Product properties

- Contained with solvent recovery, CIP

Mixing

- Batch size

- Product properties such as free flowing, segregative

Milling

- Particle size and particle size distribution

- Required capacity

- Batch/continuous process

- Product properties such as hazardous, abrasive, sticky

Agglomeration & Extrusion

- Energy savings up to 50% compared to spray drying

- The Flexomix can increase the capacity of the Bextruder up to 35%

- Easy to disperse product