Due to their diversity, different sweeteners are processed in very different ways. The demands placed on size reduction technology range from high throughput rates for household sugar and uniform particle sizes for sugar blends to sugar conditioning for shelf-stable icing sugar.

In addition, monosaccharides and polysaccharides (dextrose, glucose, sucrose, maltose, galactose and fructose) with particle sizes < 200 µm pose a high explosion risk, meaning that machines and systems need to be explosion-protected in accordance with international directives and standards.

We have taken on these challenges: We are revolutionising the sugar milling market with easy-to-integrate, explosion-protected system concepts that we custom-design according to your preferences and requirements.

Sugar

Grinding and pulverising across the entire range from coarse to fine. Effective and efficient.

As a generic term, sugar has many shapes and applications. Just to name a few, this includes granulated sugar, icing sugar, ultrafine sugar, caster sugar and instant sugar.

Your advantages at a glance:

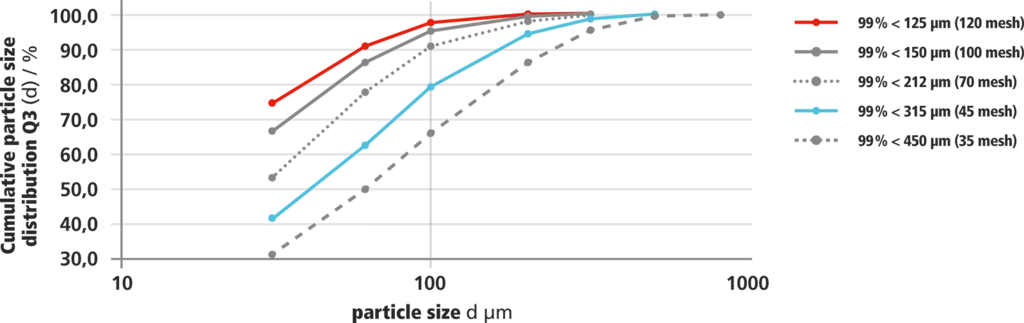

- Fineness values from 10 to 300 µm

- Steep upper particle size limitation

- Explosion protection, in accordance with the applicable ATEX directives

- Constant process management through controlled temperatures and humidity levels

- Low dust production

- High throughputs

- Compact, space-saving installation

- Low energy consumption

Icing sugar is on everyone’s lips nowadays, from baked goods and confectionery to ice cream and convenience food. That is why it pays off for many manufacturers to buy in cheap crystal sugar and grind it into the required degree of fineness themselves.

Sugarplex SX: In order to meet the special grinding requirements of this product, we introduced the Sugarplex SX sugar mill to the market over ten years ago.

The stainless steel pin mill with a pressure shock resistant design produces icing sugar without the need for filter or fan accessories.

Sugarplex Flow: In order to meet customer and user demands for icing sugar that is stable enough for storage, the Sugarplex has undergone extensive further development: the Sugarplex Flow!

What’s new? The recrystallisation takes place completely inside the mill – without the use of additives and in continuous operation.

In order to increase the range of applications for household sugar, Hosokawa Alpine presents processes for mechanical particle enlargement such as compaction and granulation. When producing pearl sugar, the particle size is usually 1.5 – 5.0 mm. End applications with this particle size include sugar as decorative sprinkles for cakes, pastries and confectionery products.

Compaction improves the handling of the sugar. Seamless transport and more precise dosing as well as increased storage capacities are the advantages for sugar processing.

Final application

Production Process

NEW: STORAGE-STABLE ICING SUGAR

Production in one and the same system

Freshly ground sugar is amorphous, readily absorbs moisture and tends to form clumps. Conventional processes require additional additives or mixers which not only have high requirements in terms of space, time and maintenance, but are also limited to batch-based production.

The call for a simplified and flexible process for producing storage-stable sugar through complete recrystallisation is growing louder and louder. Hosokawa Alpine has risen to this challenge and presents the solution with its Sugarplex Flow: Thanks to innovative process management during grinding, the adjustment screws are perfectly coordinated to ensure a defined moisture content via precise temperature control and optimised residence time. The broken, amorphous sugar crystals can be transformed into a stable form in a controlled manner.

The product exits the mill completely recrystallised and stable for storage – without the tendency to form deposits or clumps.

- Complete recrystallisation inside the mill saves space and reduces the process steps

- Shelf-stable icing sugar without the need for additives

- Highest quality in the storage and production of confectionery products

- Flexible and safe process through continuous operation

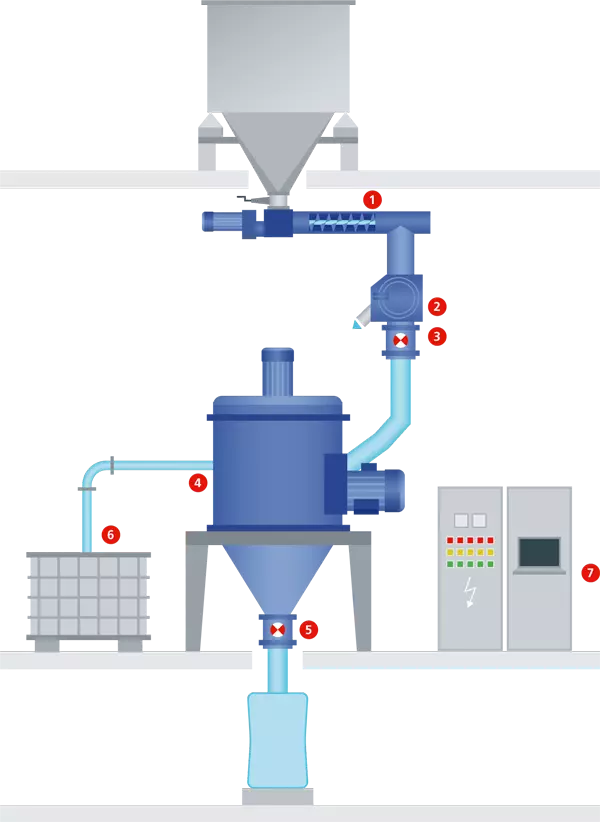

Principle of operation: the right process is crucial

The granulated sugar is fed through the mill door by a rotary valve directly into the centre of the grinder. The grinder, which is composed of two pin discs, is completely integrated into the mill door.

The door can be opened quickly and easily. The grinding tools can be inspected at any time and cleaned without any issues at all. A frequency converter can be used to regulate the motor speed via stepless adjustment and to set the required fineness value.

The recrystallisation time is shortened by the precisely controlled atmosphere inside the mill. Amorphous icing sugar can crystallise in the mill before being discharged via a rotary valve.

1 Dosing screw

2 Metal separator

3 Rotary valve

4 Mill

5 Rotary valve

6 Conditioning unit

7 Process automation

TECHNICAL HIGHLIGHTS

Designed according to your requirements

- Perfect residence time: The residence time of the sugar in the mill can be adjusted perfectly by means of design and process engineering modifications in order to achieve complete recrystallisation and therefore shelf-stable sugar.

- Ideal balance: The integrated agitator in the grinding chamber provides an ideal balance between the set moisture level and the freshly ground icing sugar. This prevents the formation of undesirable agglomerates.

- Precisely regulated: The atmosphere required for recrystallisation is precisely controlled and adapted to the overall process through the use of a conditioning unit.

- Optimum temperature: The use of heating sleeves accelerates the start-up process and prevents condensation on the contact surfaces concerned. We ensure a safe and continuous process for your system.

Technical specifications

Icing sugar fineness model – produced on the Sugarplex Flow