Thickening agents

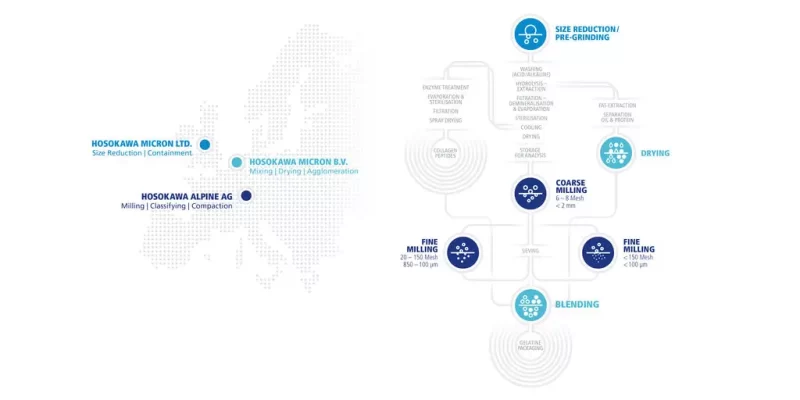

The manufacture and processing of thickening agents and hydrocolloids such as gelatine, carrageenan, pectin or guar is a complex process and includes highly technical processing steps. Applications for the products are multifarious: desserts, confectionery, sauces, cheese or meat preparations.

To ensure that the typically specific characteristics such as mouthfeel, thickening performance and stability remain constant, the thickening agents must also have a uniform structure.

The Hosokawa Group has a comprehensive fund of expertise in the manufacture and processing of animal and vegetable thickening agents.

Gelatin

Our systems are typically used for the coarse and fine grinding of dry gelatin obtained from extruded material. The coarse, dust-free and free-flowing qualities are produced with a granulator, whereas the higher fineness values are achieved with a fine impact mill. Dependent on the required steepness of the particle size distribution the ground gelatin is fractionated even further with a screening machine.

- Uniform particle size

- Steep particle size distribution

- Low-dust production

- Free-flowing powder

- Smooth process sequence

Final applications

Vegetable Thickening Agents – Carrageenan, pectin, etc.

To permit replacing thickening agents of animal origin, products such as carrageenan and pectin are still on the increase throughout the world. The typical fineness values here are in the < 250 µm range and finer, which is why it is predominantly the ACM classifying mill that has established itself for the grinding step.

The advantage of this type of mill is in the cooling and a steep particle size distribution with a sharp top-size limitation effected by the dynamic classifying principle. Adjusting the classifying wheel allows requirements in terms of different reproducible product qualities to be realized.

- Uniform size reduction in the preliminary process

- Cool pulverisation for gentle processing

- Uniform particle sizes < 250µm

- Sharp top cuts

- Low-dust production

- Free-flowing powders

- Smooth and efficient process sequence

Final applications

Drying and grinding applications

For the application of drying and grinding extracted alginate, gelatine and caseinate, Drymeister DMR-H is suited for one process production.