DRYING

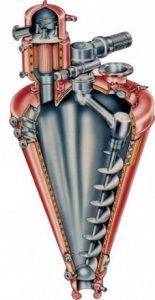

Direct Heating Flash Dryer

Drymeister DMR-H

- Combination of drying, de-agglomeration/milling and classifying in one piece of equipment.

- High drying ability and no adhesion inside.

- Fine and dry product.

- Easy control of particle size.

- Easy control of moisture content in the product.

- Compact installation.

- High energy efficiency.

- Various options:

- Construction material of ceramics for the powder contact parts.

- Specially designed screw feeder for cake material.

- Compared to conventional Drymeister, DMR-H can:

- induce inlet air temperature up to 600°C

- increase capacity by 40%

- improved thermal capacity coefficient.

Multipurposed-Domed Type with Jacket

Hosokawa Vrieco Nauta Vacuum Dryer

DBX-RWV,NXV

- High heat transfer coefficient : Material dependence, but normally U=50-2000W/(m2•K)

- Low energy consumption.

- ca. 5.5-13kW for 2,000 liter/batch size.

- Limited gas tight part.

- Easy discharge and very little residue in the vessel.

- Easy to clean.

Indirect Heating Agitating Media Dryer

Xerbis XB

- Slurries/Solutions can be directly dried.

- Drying slurries with high viscosity and cohesive nature.

- Energy saving.

- With a closed circuit system, running cost can be drastically reduced.

- Wear protection.

Lyophilisation

Active Freeze Dryer AFD

- Efficient and contamination-free.

- Faster and less labor intensive than the traditional tray freeze drying process.

- High Quality.

- Compact.

- Typical applications include pharmaceuticals like antibiotics, proteins, collagen and API’s, and food & food additives.

Indirect Heating Dryer

Thermo Processor MTD

- Wide application with different rotor designs.

- F type has higher plug flow property suitable for low moisture material.

- M type has higher mixing ability suitable for sludge like material.

- High heat transfer efficiency.

- Reduce adhesion due to dual rotor construction.

- Compact unit with large heat transfer area.

- Large heat transfer capacity and heat transfer coefficient.

Indirect Heating Dryer

Solidaire SJ

- High dispersion effect enables to dry high moisture content material and caked material to product moisture content to several %.

- Paddles break the agglomerates contained in the material and avoids secondary agglomeration generated while drying to produce powdery products.

- Drying time can be controlled by adjusting angles of paddles and/or rotating speed of rotor.

- With inert gas operation such as N2 as a carrier, it is possible to operate.

Indirect Heating Dryer

Torusdisc TD

- Compact structure with large heat transfers area. Reduced heat loss to outside, and effective use of heat energy.

- High heat transfer coefficient.

- Dry powder, heat transfer coefficient is 20-35kJ/m2•h•K

- Wet powder; 30 – 60kJ/m2•h•K

- Slurry, 60 – 230kJ/m2•h•K.

- Wide operating application for drying, heating, cooling, vacuum drying and combined operation with hot air.