TODAY HIGH END QUALITY GCC WILL SECURE YOUR SUCCESS

What count is:

- consistent particle size distribution

- perfect top cut of coated and uncoated GCC

- perfect coated GCC for polymer industry

- GCC slurry or powder for paint applications

- designed particle size distribution,

ULTRAFINE DRY PROCESSED GCC

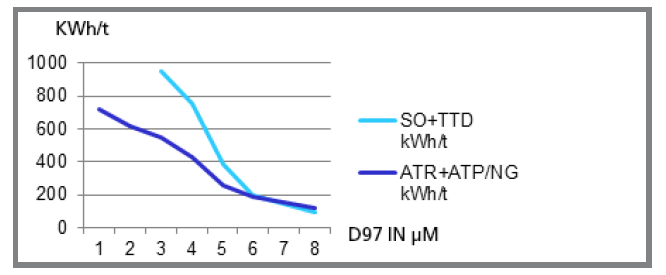

THE ULTIMATE DRY PROCESS FOR GCC DOWN TO D97 = 2.2 µm

- upgrade your GCC product range portfolio into the ultrafine range

- target the polymer, paint and paper industry

- with consistent high quality slurry

- very stable and consistent particle size distribution

- assures highest whiteness degress

- low energy dry processing solution D97 = 2.2 to 10 µm

- high capacity for ultrafine GCC fillers and extenders

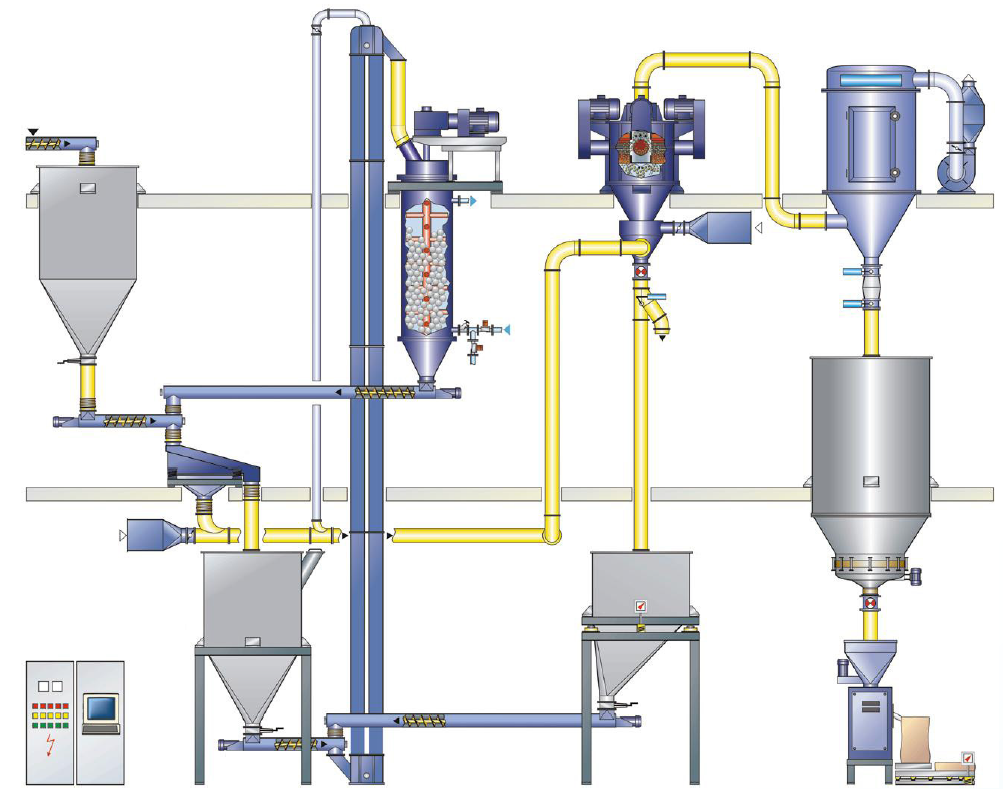

- the ATR in closed circuit with the latest ultrafine ALPINE Multiwheel Turboplex ATP or TTD

- get direct your desired GCC ultrafine filler

- upgrade your ball milling process by the ATR system

Brochure_Calcium Carbonate (GCC)