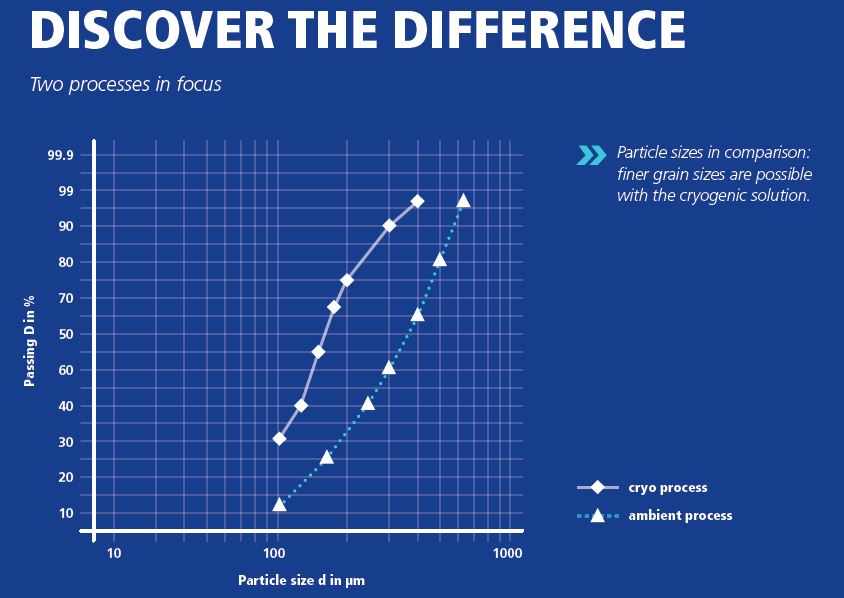

Whether tire rubber or technical rubber from production: customers of diverse application areas benefit from Hosokawa Alpine’s solutions for cryogenic and ambient rubber grinding for maximum fineness. This task places special demands on machines and systems. For example, it is important to coat the grinding tools, as they otherwise wear out more quickly due to the fillers in the rubber which can lead to machine downtimes. Here, Hosokawa Alpine has developed special solutions for both ambient and cryogenic grinding.

Another challenge to the process is that finely ground rubber is very flexible and yields during screening. This complicates the screening process and requires special solutions, especially when classifying finenesses < 180 µm. The Stratoplex ASP II air classifier provides a remedy: the classic air classifier from Hosokawa Alpine can separate very fine fractions (e.g. 75 µm, 125 µm, 180 µm …) from the ground material. For coarser fractions, a centrifugal screen is installed in the ambient system.

AMBIENT GRINDING

New technologies for the grinding of rubber

The feed material is ground by means of pressure and shear stress. We can now deliver the highest-quality machines for your plant and product safety in the ambient grinding of rubber. We have combined our know-how to offer you customised process technologies for optimum solutions.

Features and benefits of ambient grinding:

- End fineness easily achievable by using an in-line screening machine

- No oversized product due to closed-loop process

- Fine powder with very good flowability and a high surface quality

Ambient grinding solutions by Hosokawa Alpine’s Rubber Powder Mill (RP)

The Hosokawa Alpine Rubber Powder Mill (RP) works continuously in grinding and classifying. It can handle all rubber types with more that 45 Shore. Due to grinding technology, a very low energy consumption without cooling process (process temperature 60 – 85 °C) is possible. The grinding tools have slowly rotating tips and are silent in operation. The grinding and classifying process is performed in a closed loop without oversize particles. The classifying step uses a specially designed screen which is interchangeable for different application/requirements.

Our solutions

- Active rubber powder from 10µm – 1000µm with very large surface energy

- Reduced material costs

- Great mixing ability of the active rubber powder

- Time-reduced vulcanisation

- Mixing up to 80% in the production of TPE

| RP 500 | RP 600 | ||

|---|---|---|---|

| Throughput capacity (kg/h) | up to 300 | up to 400 | |

| Process temperature | 60 – 85 °C | 60 – 85 °C |

| Particle size | Percentage |

|---|---|

| < 100 µm | 12 % |

| < 160 µm | 24 % |

| < 250 µm | 40 % |

| < 315 µm | 52 % |

| < 400 µm | 67 % |

| < 500 µm | 82 % |

| < 630 µm | 98 % |

CRYOGENIC GRINDING

Find your optimum solution for the grinding of rubber

The feed material is cooled down to the “glass transition temperature” by liquid nitrogen. With the specially designed Hosokawa Alpine Contraplex CW II pin mill – in combination with our Stratoplex ASPII classifier – we guarantee innovative technology from one single source for highest quality in grinding of rubber.

Features and benefits of cryogenic grinding:

- Fractions below 125 μm at high yield and very low “oversize” content

- Fine powder with very good flowability

- Separation of different fractions with Alpine Stratoplex ASP II classifier

- Fine powder in cubic form with a smooth surface

- High relative speeds for grinding to a high fineness

Depending on the application and market, finer fractions (e. g. < 180 μm, < 125 μm) are sometimes required. Due to the fact that it is not possible to grind rubber granules any finer in an economical way, it becomes necessary to separate a finer product (fraction) from the cryogenic process downstream. For such applications, the Alpine Stratoplex ASP II turned out to be the ideal machine with regard to yield, efficiency and investment costs.

- Standard air classifier for high throughputs in the fine to medium-fine separation range of d95 = 75 to 180 μm

- High fines yield at high precision of cut and high loading

- Low energy consumption

| CW II 250 | CW II 400 | CW II 630 | CW II 800 | ASP II 315 | ASP II 400 | ||

|---|---|---|---|---|---|---|---|

| Throughput capacity (kg/h) | 200 | 500 | 900 | 1400 | 800 | 1500 | |

| Process temperature | at glass transition point | at glass transition point | at glass transition point | at glass transition point | ambient | ambient |

| Particle size | Percentage |

|---|---|

| < 100 µm | 31 % |

| < 125 µm (120 Mesh) | 41 % |

| < 160 µm | 60 % |

| < 180 µm (80 Mesh) | 68 % |

| < 200 µm | 76 % |

| < 300 µm | 91 % |

| < 425 µm (40 Mesh) | 96 % |

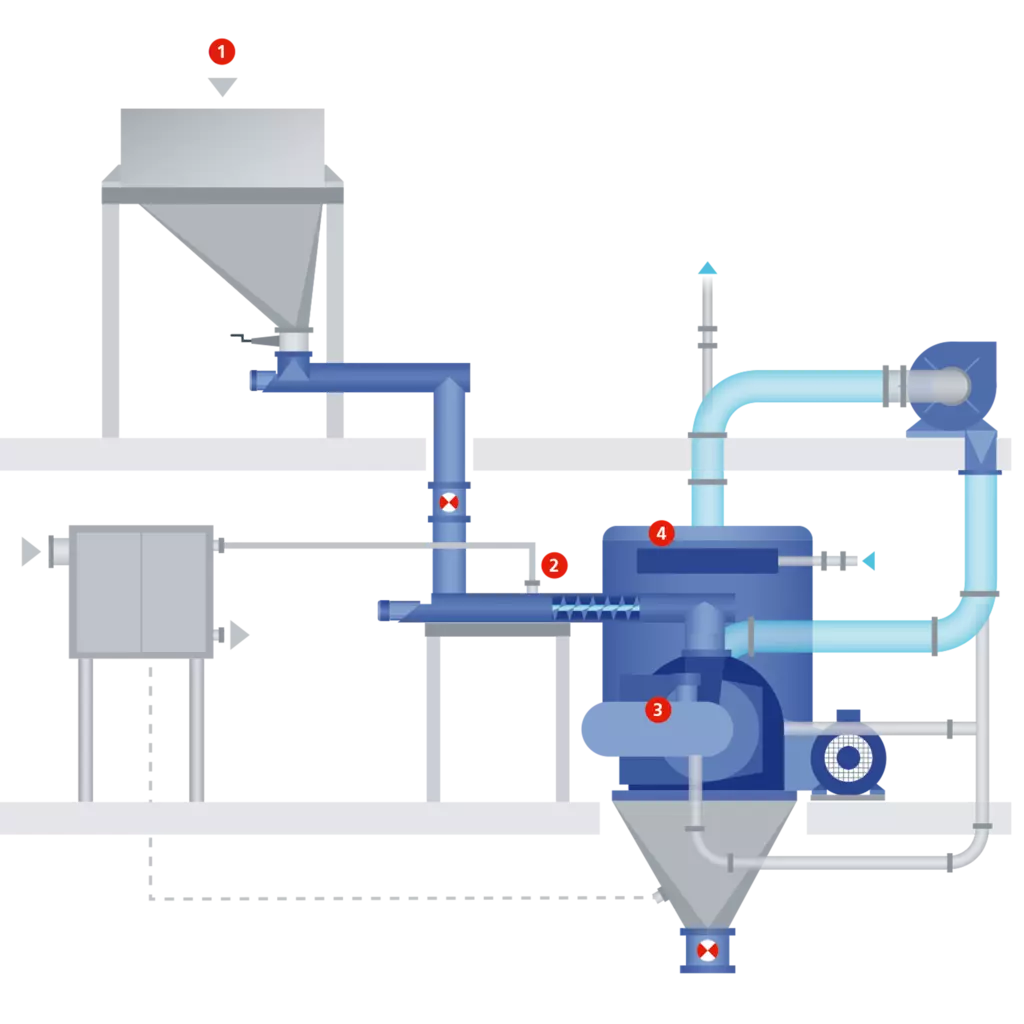

DEFINE YOUR PROCESS

Schematic diagram of cryogenic grinding

- Dosing unit

- Cooling screw

- Alpine Contraplex CW II pin mill

- Filter system