AGGLOMERATION

Compactor

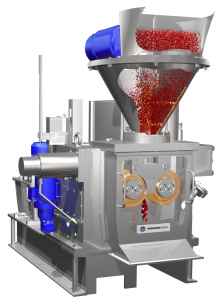

CS Roller Compactor

- for compaction, granulation and briquetting

- for abrasive products

- for frequent product changes

- for laboratory applications in the mineral and chemical industry

- easy to maintain and robust

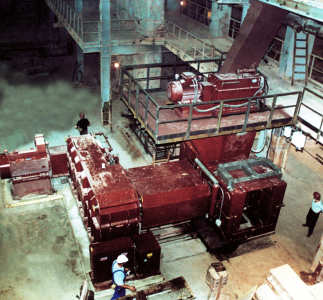

Compactor

MS Roller Compactor

- Minerals/Metals:

- Dedusting by briquetting

- Granulate production, e.g. fertilizer

- Chemicals:

- Improve flowing properties and storage life of powders

- Increase bulk weight

- Improve flowing behavior of powders

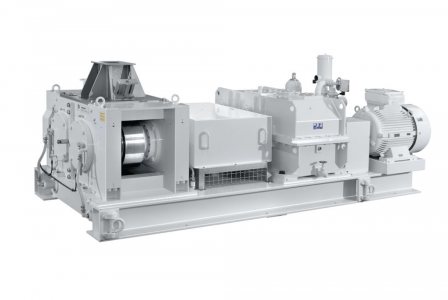

High Pressure Roller Mill

Compact mills for sharp-edges granules

- Pre-crushing before fine grinding

- Non-fine crushing

- Sharp-edged granules

- Narrow granule distribution

Compactor

Pharmapaktor C 250

- Pharmaceutical production

- Pilot operation and development (galenic)

- in the case of frequently changed products

- in the case of temperature sensitive products

- Insulator application

Compactor

Pharmapaktor L / Pharmapaktor K

- Pharmapaktor L

- in case of high press forces

- in case of frequent product changes

- in case of small to medium batch sizes

- Pharmapaktor K

- Production machine for large batches

- in the case of high press forces

- in the case of temperature sensitive products

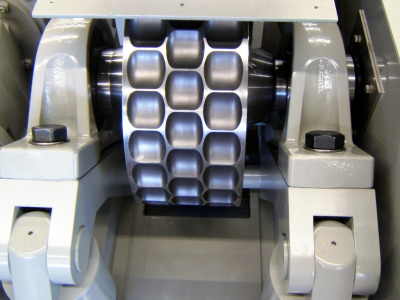

Compactor

Kompaktor HK

- Briquetting of charcoal

- Roller diameter: 400 mm

- Working width: 150 – 200 mm

- Drive unit 5.5. – 7.5 kW

- Gravity fed

- Roll tyre

Fluidized Agglomerator

Agglomaster AGM-PJ

- Diversity in functions

- mixing

- dispersion

- agglomeration

- coating

- disintegration

- drying

- Equipped with pulse jet dispersion mechanism.

- Possible to agglomerate the ultrafine particles below 50μm.

- Possible to coat of the ultrafine particles about 10μm.

- Possible to control agglomerates size by pulse jet mechanism

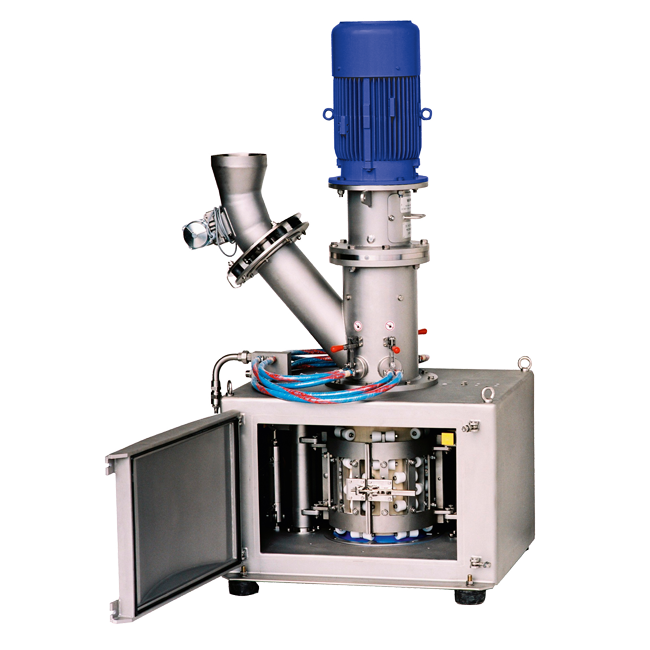

Continuous Agglomerator

Flexomix FX, FXD

- The Flexomix continuous agglomeration system is a powerful combination of a number of functionalities:

- Powder handling system

- Powder dosing system

- Binder dosing system(s): water, steam, and other liquids

- Schugi® Flexomix mixer and agglomerator (FX),

- Schugi® Fluid Bed Dryer and Cooler (FBD)

- Air system including blower and heating/cooling equipment

- Air exhaust system including cyclone and filter

- Product classification and size crusher (if necessary)

- State-of-the-art integrated control system

- Applications:

- Chemical

- Super absorbent polymers (SAP), detergents (drying, compounding before cooling, agglomeration), LIB anode phosphate (hydro exothermic reaction), pigment, or pesticide.

- Mineral/metal

- Nickel/cobalt (compound or agglomeration for LIB cathode), graphite (for secondary battery), tungsten carbide (for molding material), carbon black (for press material).

- Food

- Instant food (dairy product, cocoa, soup for vending machine), animal feed, bakery additives, spice, flour (wetting), starch (reforming), milk substitute.

- Pharmaceutical

- Animal antibiotics, lactose.

- Chemical