Primary particle size of carbon black is usually 10 – 500 nm of carbon super fine particles. It is used for reinforcement of rubber, pigment and conductive materials. Nearly 70% of carbon black product is used in tire manufacturing. Carbon black is produced from the incomplete combustion of petroleum products such as oil and tar. By controlling particle size, structure and surface conditions it can be suited for various applications. Carbon black is often granulated due to the very small particle size and the low bulk density.

Contents

Carbon black production naturally forms very fine particles, however the material may contain a small amount of larger particles referred to as grit. Grit consists of very fine cokes generated during the process, fragments from furnace refractories or metal rusts. High girt levels can negatively effect material quality and reduce material strength. The quantity of the grit should be controlled under certain values. Traditionally, carbon black has been ground using a Mikro Pulverizer Hammer & Screen Mill to reduce grit to acceptable levels.

Conventional technology

In a standard Mikro Pulverizer configuration, material is introduced to the mill by a screw feeder. However, since air-swept and gravity fed options have been adopted. In many cases, a herringbone screen can be used to control grit levels, but long gap screens with larger openings have been used to increase capacity.

Recently, there has been an increased demand for high quality, low grit carbon black. Air classifiers and high performance mills can be used to achieve even lower grit levels.

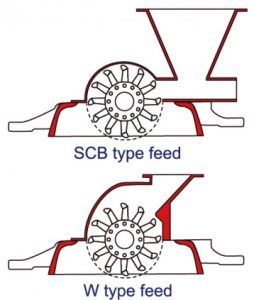

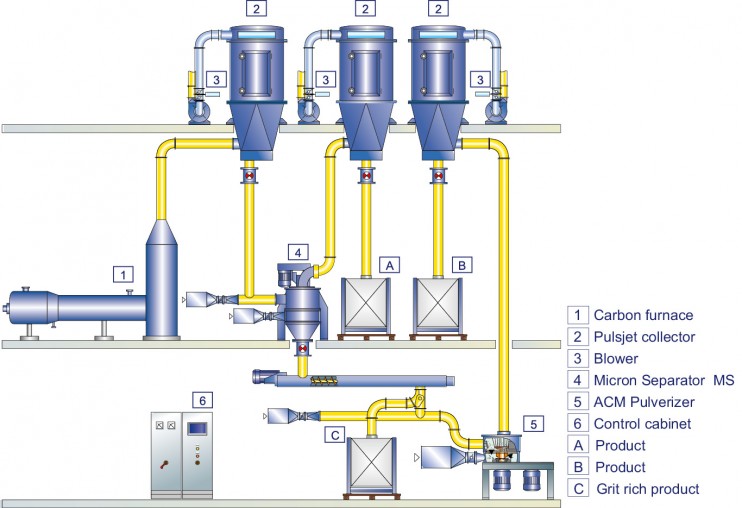

In case of air classification to remove grits, Micron Separator is the most appropriate. Carbon black can be very sticky and abrasive, therefore special attention is needed for the construction of the classifier. Due to the low bulk density of carbon black, the Micron Separator can not use the standard bottom fed configuration. Instead, materials are introduced from the top of the classifier. After the material has been classified and separated, the fines can be sold as a premium quality carbon black; the coarse materials can be reground or sold as a lower value product.

If ultra-low grit levels are required, the Mikro ACM Pulverizer is commonly used. The Mikro ACM is an air swept, impact mill with an integrated air classifier for excellent particle size control. It can be built with wear protected compounds that resist abrasion. In the actual process, there are two cases, one is grinding of the coarse powder from Micron Separator and the other is to grind the material directly without classification.

Newest technology

To meet the increased demand for high value, low grit material, the Mikro E-ACM was developed for carbon black applications. This device offers superior grit reduction and was designed specifically for carbon black. A conventional air classifying mill is not as well suited for processing light, sticky and abrasive materials.

The newly developed Mikro-eACM Carbon Black Air Classifier Mill greatly transcend the performance of conventional hammer mills. It offer superior grit reduction capabilities, are more energy efficient and have lower costs of operation.

Mikro e-ACM® Carbon Black Air Classifying Mill

- Reduces grit levels as low as < 1 PPM + 325 Mesh

- Impact milling with internal classification

- Operates in gas streams up to 200°C

- Capacities up to 10 tons/hr

- Available in sizes from 10 to 600 HP

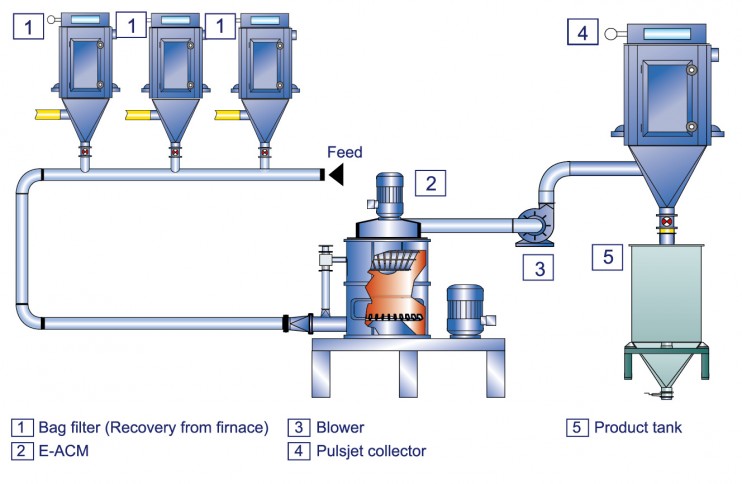

System

The mill is usually integrated in the carbon black production process with the carbon furnace as an in-line machine. To compensate the pressure loss of the mill a blower is placed after the mill.