Super absorbent polymers (SAP) are polymers that can absorb and retain extremely large volumes of liquid. Amazingly, water absorbing polymers (hydrogels) can absorb and retain up to 500 times their own weight in water. Their absorbency is determined by the type and ration of cross-linking agents used to make the gel. Low density cross-linked SAPs have a larger absorbent capacity, while the higher cross-linked SAPs have lower absorbent capacity but form firmer gels

Adding cross-linking agents

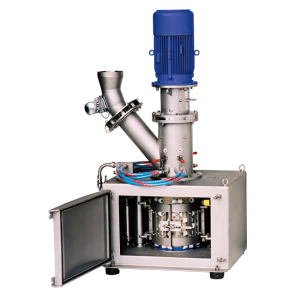

The Flexomix mixer/agglomerator is commonly used to add surface cross-linking agents to SAPs. It can be used to dose powder and liquid in the correct proportions to create a homogenous mixture and is self-cleaning to avoid product build-up which can often be a problem in SAP production

The biggest application of SAP is their use in disposable hygiene products such as nappies (diapers), adult protective underwear and feminine hygiene products. They absorb fluids to form a gel, which prevents leakage. Other uses include water-blocking applications in electrical power cables, optical cables, construction works, food packaging and agricultural soil conditioners.

Try before you buy

Not convinced yet? Consider running a test first. We have a pilot system in our test facilities in the Netherlands, which is available for testing and toll processing.