- Minimizes the negative effect of the temperature on the spice properties such as flavour and colour;

- Based on Hosokawa’s conical paddle dryer (CPD) technology;

- Three-in-one steam sterilizer, mixer and vacuum dryer for extra process efficiency;

- Batch system: maximum flexibility in terms of time & temperature parameters and batch sizes.

Spices and herbs are natural products, the mechanical processing of which merely alters the shape while ensuring that any negative impact is kept as low as possible. The successful processing of spices and herbs places complex requirements on the processing chain and is one of the most difficult tasks of size reduction technology.

Every process is individual and depends on both the customer requirements and the diversity of product properties. Important factors are the hardness, size, colour, oil content, shear resistance and viscosity of the spices, medicinal herbs, dried vegetables or roots that are to be processed. In addition, quality fluctuations due to their natural origin must be taken into account.

Within the process, this means that wear, temperature changes, fire and explosion risks must be considered. In this connection, the essential oil content plays an important role. It dictates the later market value as well as the aroma intensity in the final application. Because of this, spices require very “gentle” processing, for example by means of cryogenic grinding with nitrogen or conditioned air.

cleaning

Removal of light and heavy impurities

- Various machine sizes available

- Design as single-tube or multi-tube classifiers for sharp separations in the range of d97 = ca. 0.3 to 10 mm

- Throughputs of several kg/h up to 200 t/h

- Simple operation

- Low-maintenance and low-wear classifier

- Reliable in operation

Areas of application

Crushing and cutting

Of spices, herbs and tea

Spices, herbs and tea are reduced to uniformly fine, clean-cut granules with a minimum of dust using the Rotoplex granulators. The cross-scissor-cut rotor of the Rotoplex granulators guarantees an ideal production of fine to coarse grained products. This is why the pre-crushing of large spices as a preliminary stage to fine grinding is a typical area of application.

Areas of application

Fine grinding with maximum flexibility

For various spices and market requirements

The Ultraplex UPZ fine impact mill is known as the universal spice mill, due to its flexibly of using different grinding tools and adjustable rotor speeds. It is the mill of choice for root spices, seeds, fruit skins and husks with a high ash content and extremely hard seed pods such as rose hips. Grinding behaviour, throughput performance and product quality depend on moisture content, purity, essential oil content and origin. The mill door can be opened in a wide angle for easy cleaning.

- Various machine sizes available

- High flexibility due to easily exchangeable milling tools

- High fineness with top size limitation

- Perfect for fibrous roots and spices

- Easy cleaning and accessibility

- Dust explosion protection available

- Bearing protected against dust ingress by air rinsing

- Low energy consumption

Fine grinding with maximum performance

For oily seed spices

Together with the special drop shape of the housing, the two pin discs driven in contrary motion of the Contraplex CW II pin mill minimise deposit formation. In this way, they enable longer production times for difficult products. In counter-rotating mode, the Contraplex pin mill achieves much higher relative speeds than the UPZ fine impact mill. The fineness can be adjusted by changing the pin disc speeds. The design with the wide-chamber housing is ideal for processing moist, greasy and sticky products such as nutmeg/mace, cardamom or mustard seeds. The feed material is often embrittled by intensive mixing with liquid nitrogen.

- Various machine sizes available

- Easy access to the grinding area for cleaning and maintenance

- Finer grinding: higher speeds allow better deagglomeration and hence finest results

- Gearless drives avoid any possible contamination in the production area

- Low energy consumption

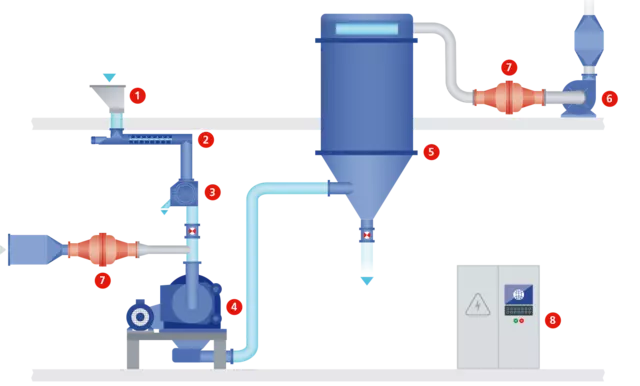

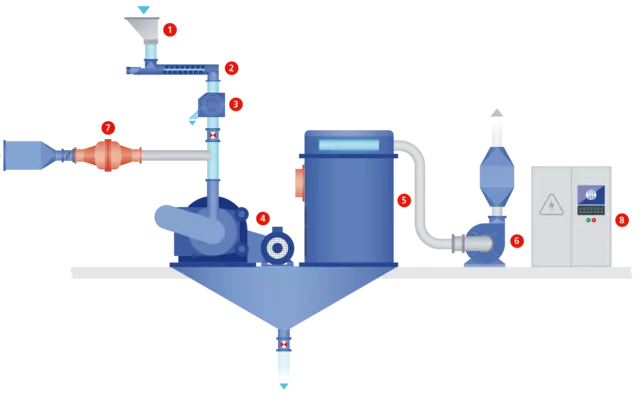

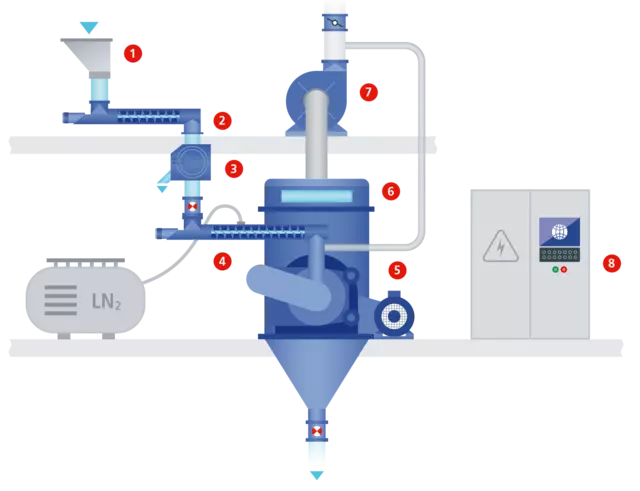

Cryogenic fine grinding

Process stability and high fineness for oily products

Heat is generated during the grinding process, which has two consequences: Firstly, the essential oils evaporate, and secondly, the heat-sensitive fats melt. In the worst case, this can cause the grinding elements to clog up and the entire mill to block and stall. This is prevented by cryogenic grinding with mainly liquid nitrogen as a cooling agent. Here, the cooling agent can either be injected directly into the mill or the material can be pre-cooled and embrittled in a whirling motion cooling screw.

As the loss of essential oils is considerably less with cryogenic grinding than with grinding at ambient temperature, it is possible to improve the aroma and flavor. In addition, the grinding performance is about twice as high, and the risk of fire is eliminated.

For some spices, it can be beneficial to opt for cool milling (at +5⁰C to +20⁰C) or cryogenic milling (at -80⁰C to -10⁰C) instead of ambient milling. Cryogenic milling enables higher powder fineness, longer product shelf life and reduced evaporation of essential oils, thus better preserving the flavour properties. In the case of white pepper, for example, cryogenic milling retains 94.5% of the essential oil content, compared to just 57.8% retained when it is finely milled at ambient temperature.

Our systems are designed especially for operation under cryogenic conditions. These include:

- Insulation of the closed-circuit system

- Stainless steel design on account of condensation

- Cryogenic control valve unit for exact dosing of the requisite amount of liquid nitrogen

- Whirling motion cooling screw to cool the feed product

- Temperature control, oxygen monitoring

- Supplied by end user/customer: Vacuum-insulated nitrogen tank, ductings and tubing

Mixing/blending

When it comes to selecting the right equipment for the mixing/blending operation, it is important to match the amount of shear introduced during the mixing operation to the properties of your spice powder – such as fragility, cohesiveness and the fat/oil/fibre content. This will enable you to achieve optimal homogeneity while preserving the product quality and not damaging the product integrity. Hosokawa Micron generally recommends one of the following two batch mixers for spices:

- Nauta® conical screw mixer: Low-shear mixing operation offering a high mixing accuracy for a variety of spices, even the most delicate ones;

- Vitomix ribbon screw mixer: Twin-screw, low-to-medium shear offers a fast mixing operation in which the mixing intensity can be adjusted to different types of spices. The Vitomix is often used for the homogeneous introduction of liquid oils/flavours into spice mixtures.

Sterilization

Safety and hygiene

- Machines are designed for optimum cleanability;

- Often available with a fully automated cleaning in place (CIP) system;

- Avoid cross-contamination between different batches of spices;

- Comply with food safety regulations;

- Optimize production efficiency by reducing downtime;

- Operator and system safety (CE/ATEX compliance).

Download Spice Processing brochure