Compaction

HOSOKAWA MICRON (MALAYSIA) SDN BHD

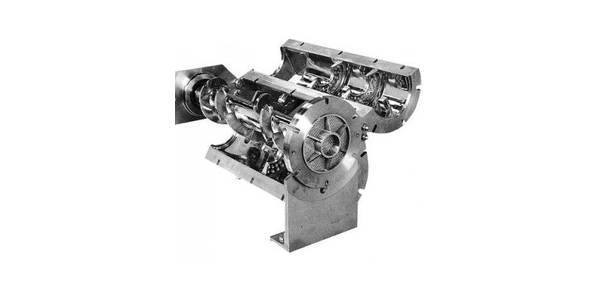

Roller Compactor

Briquetting Machine, Compactor CS MS

– Roller press.

The most economical way for briquetting and compaction.

– Briquetting.

The size of the briquette normally starts at 10 mm and goes up to 120 mm.

– Compaction.

The compaction process is normally used to

form dust free granules to less than 10 mm.

Roller Compactor + Crusher

Pharmapaktor + Flake Crusher

C250 or L200/50P + FC

– C250 : Designed for pharmaceutical industry.

– L200/50P : Pharmaceutical, food and chemical Industry.

It has small capacities up to 150 kg/h.

Very robust machine; specific pressing forces up to 30 kN/cm.

– Clean and simple construction

Gear Roll Compactor

Gear Pelletizer GCS GMS

– Can be produced cylindrical pellets with controlled hardness.

– Easy to disassemble and clean gear rolls.

– Can be heat and cool the feed.

– Can be decrease binder volume.

Fluidized Agglomerator

Agglomaster AGM-PJ

– Diversity in functions.

– The unit is equipped with pulse jet dispersion mechanism.

– Short process time.

– Space-saving, energy saving, low running

cost.

– 4 kinds of agglomeration effects :

Fluidising, agitating, tumbling, and pulse-jet.

Agglomaster AGM-SD

– Single unit produces agglomerates from liquid

material by the combination of spray agglomeration

and fluidized bed agglomeration by

unique agglomeration cycle “Layering”.

– Realize the value-added agglomerates.

– Possible to batch or continuous operation.

– Easy cleaning.

Continuous Agglomerator

Flexomix FX,FXD

– Highly soluble agglomerates. (instant product)

– Continuous process.

– Short residence time.

– Compact machine with large capacity.

– Saving energy process.

– Highly applicable for high liquid adding ratio.

– Extremely high mixing ability.

– Multi components processing.

– Self-cleaning mechanism.

– Easy maintenance.

Continuous Extruder

Extrud-O-Mix EM

– Cylindrical and hard agglomerates.

– High kneading ability.

– Possible to process several materials at once.

– Improve powder handling.

– Continuous process.

– Easy cleaning.