Due to the increasing market for convenient food products, the instant characteristics of food and beverages are gaining importance. This ‘instantizing’ technology applies for many products like instant cocoa, dry soups and the wide variety of products provided by vending machine. In most cases, original powders are not sufficient instant product. The powders may float or become jelly lumps in water/milk. The properties of the powdery products have to be optimized to achieve a better wettability and solubility.

CONTENTS

Agglomeration

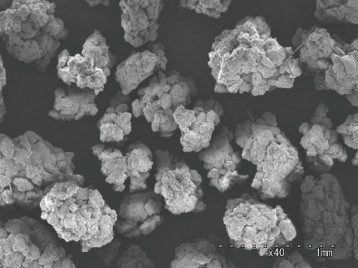

Agglomeration is the solution to improve instant characteristics. By forming the porous agglomerates, the characteristics are optimized.

In order to produce a constant and reproducible product at high rate, continuous process would be preferable. The Flexomix continuous agglomeration process would be the most appropriate for the production of the porous agglomerates of the size between 200 and 1500 μm with raspberry structure.

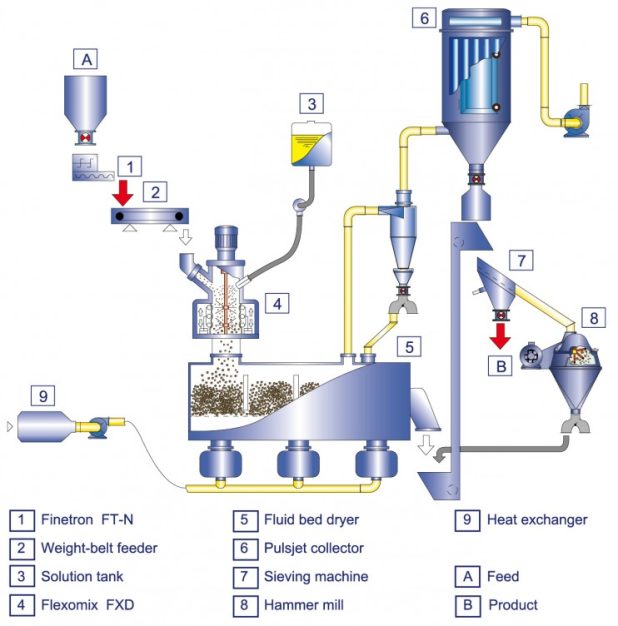

Continuous agglomeration system by Flexomix requires the equipment shown in the flow diagram shown below. However, the actual process has to be designed on each application.

As the product made by Flexomix system is the porous agglomerate (raspberry structure), it shows high solubility. It is very applicable to the instant cocoa, instant soup, coffee, noodle soup, and daily product including the product for vending machine.

MIXERS FOR INSTANT SOUP INGREDIENTS

Instant soups were introduced on the market more than 60 years ago. Initially, the amount of choice was limited and recipes were simple (starch, salt, fat, colourings and flavourings). Since then, the world of instant soups has grown substantially. One important accelerator has been the improved quality and variety of ingredients that has managed to keep up with ever-changing consumer tastes and expectations.

Today, instant soups have healthy looking ingredients such as freeze-dried vegetables, croutons, vermicelli and mushrooms. These ingredients need to be visible and recognizable by the consumer, whilst producers also put valuable time and money into other requirements such as good flow properties (for effective processing in the factory) rapid, dust-free and lump-free solubility, and of course taste!

These improvements, combined with rising production costs, have led manufactures to scrutinize the production processes over the past decades. At Hosokawa Micron, we have followed these developments closely, and produced a mixing technology that is perfect for the manufacture of instant soup.

Challenges in mixing instant soup ingredients

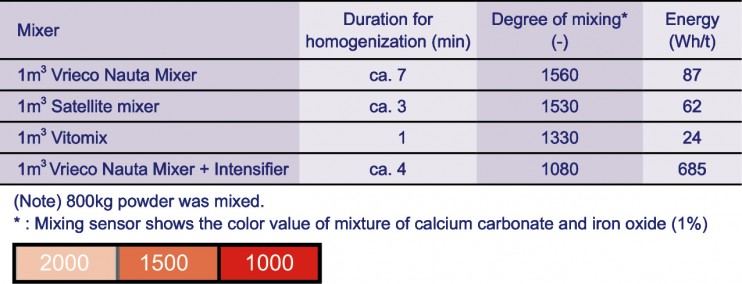

The challenge in the mixing of instant soups lies with the complexity of the recipes. These vary greatly in terms of composition and properties, resulting in two different mixing phases. Conventionally, these are handled by two mixing processes: a ‘high shear’ and a ‘low shear’ step.

During the high shear mixing step the basic ingredients (powders) are mixed intensively with oil/fat, aromas and flavourings. In order to achieve a homogenous mixture and avoid build-up of agglomerates (lumps), a great deal of mixing energy is required. A conventional mixer used for this process would be a plough shear mixer, possibly fitted with choppers. The base mixture produced with this mixer would be fed to a low shear mixer.

In the second mixing step, the base mixture is further mixed with fragile ingredients such as leafy vegetables, mushrooms and croutons. Here it is important not to apply too much energy, and therefore use a low shear mixer. In many cases, a Nauta® conical mixer is used here. It mixes accurately with minimum damage to the product and is used simultaneously as a live hopper for feeding the packaging line.

Vitomix: the smart solution

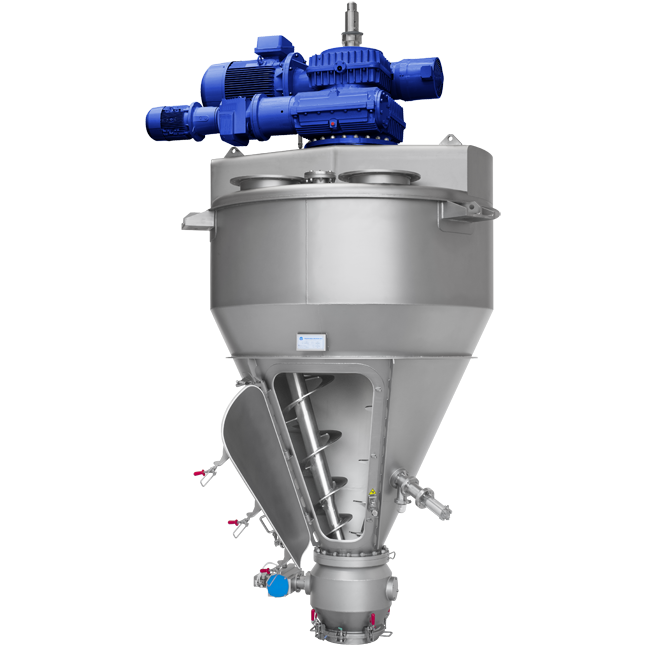

Hosokawa Micron’s Vitomix mid-shear, ribbon screw blender, provides both functionalities in one machine, thereby reducing cleaning time, intermediate storage and logistics as well as improving quality of the end product. After all, that’s what it is all about: helping our customers improve their products.

During the mixing process, the product is liquefied by two conical ribbon screws. The integrated sprayers atomize the liquid directly onto the very rapidly moving product surface, which creates the perfect conditions for adding liquids, without the formation of agglomerates (lumps), and without making compromises on mixing speed. As a result, choppers in the mixer wall are unnecessary.

Interim storage has become superfluous; and cleaning and logistics are simpler and quicker because the same mixer can be used for mixing in the fragile ingredients with the same amount of care and accuracy. The conical vessel with central outlet guarantees a very high yield, batch after batch, often without the need to clean in between batches.

The mixer is equipped with a large ISEM ball segment valve (up to DN400) for complete discharge and can be fitted with a large water-cut, hinged access door for easy cleaning and inspection as well as CIP cleaning facilities.

Proven solution

Hygienic