HOSOKAWA ALPINE’S WET PROCESSING TECHNOLOGY IN GCC

What count is:

- upgrade your GCC product portfolio into the ultrafine range

- target the polymer, paint and paper industry

- with consistent high quality GCC

- very stable and consistent particle size distribution

- assures highest whiteness degrees

- low energy processing solution of GCC of 99% to 60% , 2 µm as slurry, coated or uncoated powder

- highest capacity for ultrafine GCC fillers and extenders

- low capital investment

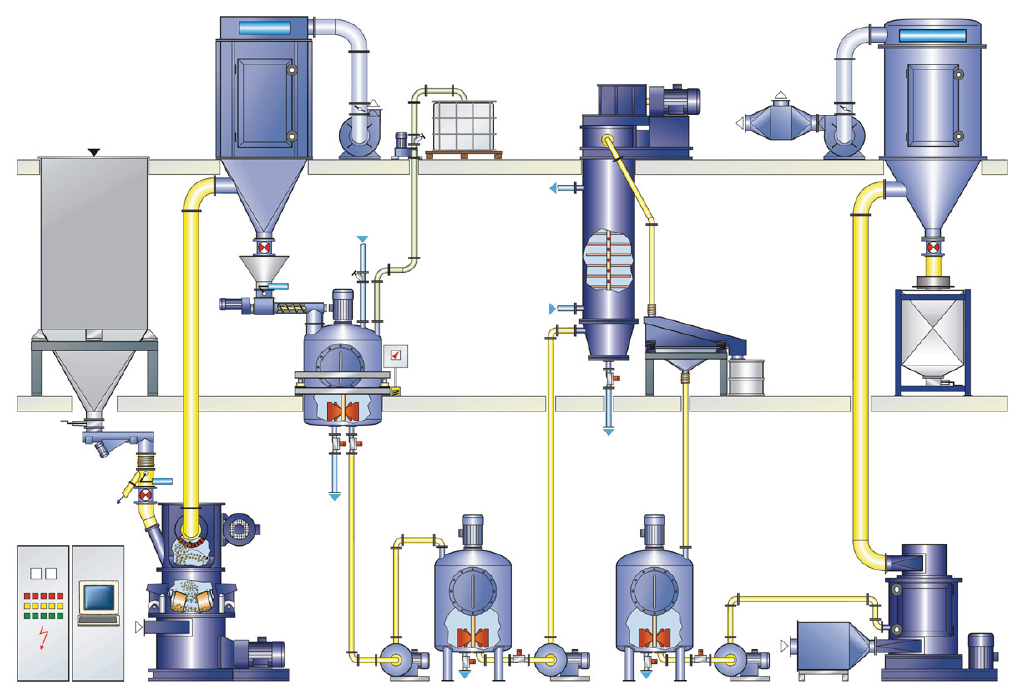

ANR-CL WET PROCESS

- up to 99% < 2 µm

- very low energy consumption

- small foot print solution

- 4 motor one gear drive

- steep PSD

- integrated classifier

- no inlet screen – no blocking

- low maintenance cost

- optional “hot grinding”

DRYING/COATING PROCESS

- low energy drying/coating

- top cut control by integrated classifier

- back mix process

- top dispersed dry GCC

- controlled coating GCC

- high capacity

- very low wear rate

- low maintenance cost