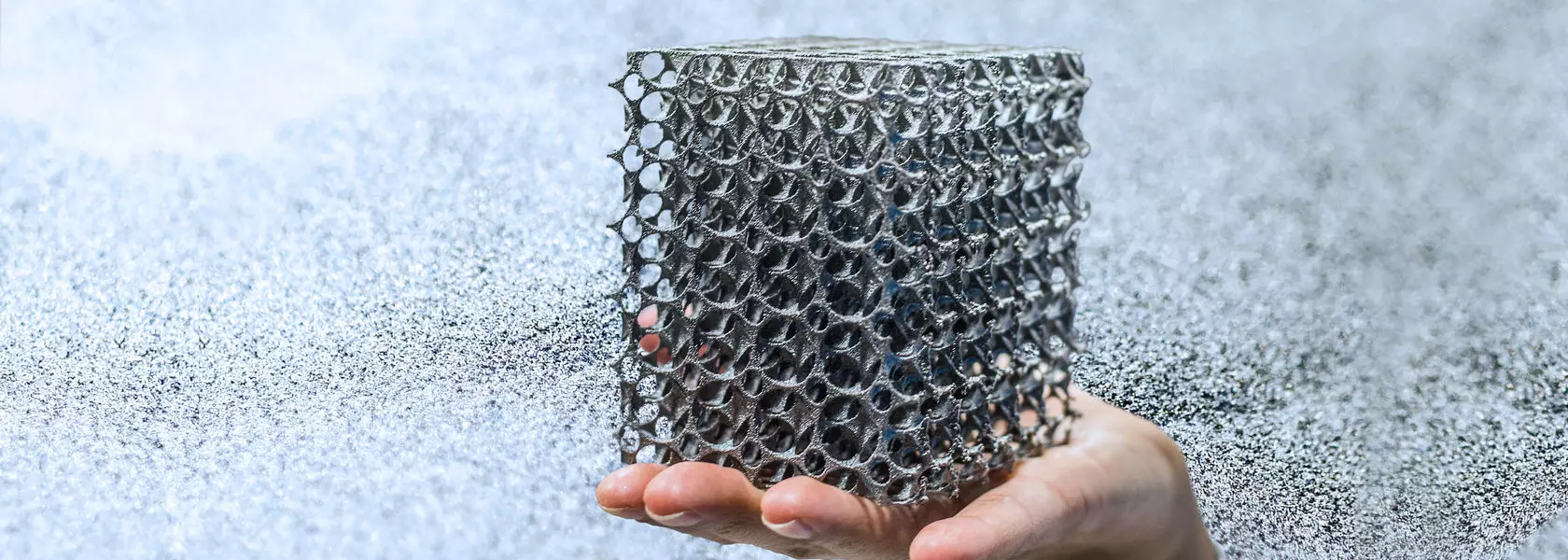

Metal powder classification for 3D printing

With its classifiers for powder manufacture, which have already proved their worth a hundred times over in successful use, Hosokawa Alpine develops unique technologies for the widest array of industries.

The machines, designed for extremely precise classification and simplest cleaning, have now been specifically adapted to the requirements of metal powder production.

PERFECT METAL POWDERS CALL FOR OPTIMUM CLASSIFICATION

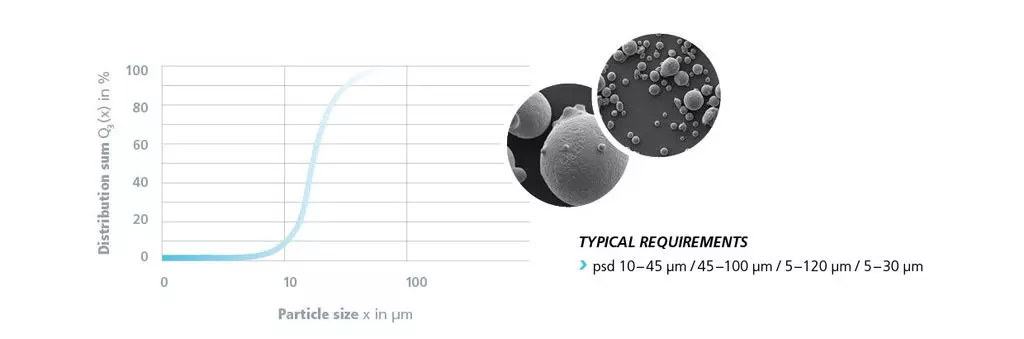

Conventional sieving machines remove the coarse particles that accumulate during atomisation of the metal powder in a pre-classification step. This technology, however, soon encounters its limits when flexible separation cuts, inert gas operation or more frequent product changes are required. An optimum solution is now available: an air classifying system with a Hosokawa Alpine Turboplex ATP classifier.

- The tried-and-trusted Hosokawa Alpine Turboplex ATP provides flexible separation cuts in the range of 5 to 120 µm

- Available in many different machine scales, matching the atomizer output rate

- Inert gas operation with argon or nitrogen

Particle size distribution of a classified Titanum-/Alloy-Powder

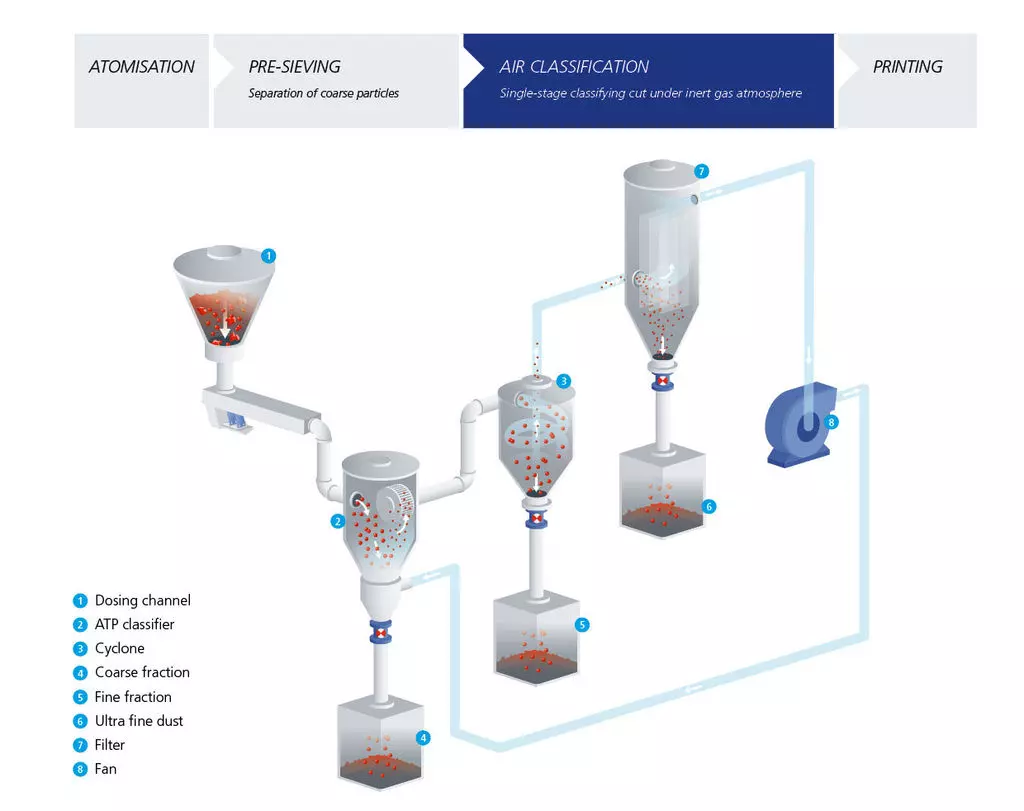

Closed circuit processing plant

We will find the optimum solution for you!

- Inert gas operation in circuit mode at lowest O2 concentration

- Separation cut adjustable without opening of the system

- On demand accesssories: gas-tight docking solutions and sampling units

- Precise removal of fine particles

- Steep particle size distribution

- Stable powder qualities at ultrafine product grades

- Dust-tight and gas-tight versions

- Minimized cross contamination at product changes – easy clean design

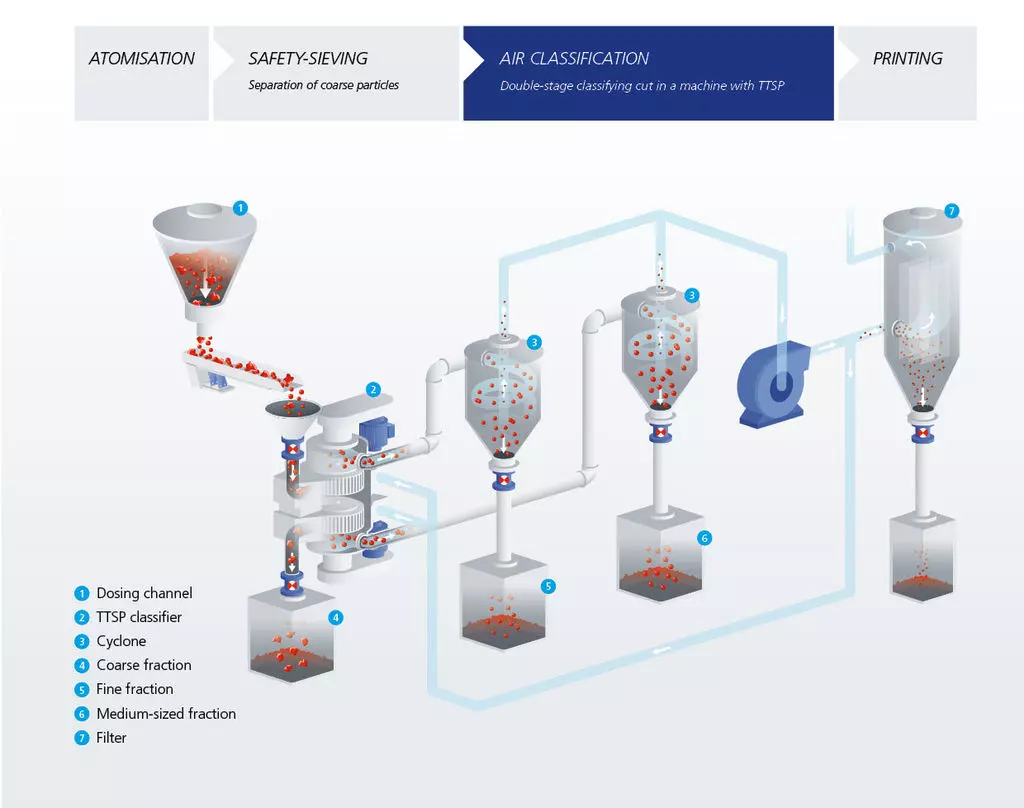

SINGLE-STAGE OR TWO-STAGE CLASSIFICATION?

The choice is yours!

Whether a filterless classifying line in circulating air mode or two-stage classifying in inert gas circuit mode is involved – we will find the optimum solution for you!

- Inert operation in gas circuit mode

- Continuously adjustable separation cut of approx. 5 – 120 μm

- Precise removal of fine particles

- Steep particle size distribution

- High yield

- Dust-tight and gas-tight versions

- Containment solutions for CMR substances