PROCESS SYSTEMS FOR GYPSUM POWDER

Hosokawa Micron provides excellent mixing and drying solutions for gypsum powder, for example in the production of fertilizers or construction materials such as plaster (plasterboard) or as a concrete additive.

Gypsum drying

In most cases, the dry gypsum needs processing. Sometimes the water hydrate needs to be removed, resulting in a hemi-hydrate or anhydrite form. Whatever form is required (di-hydrate, hemi-hydrate or anhydrite), it is always very important to control the hydration state. The dryer you select should be able to control this state closely. One excellent choice would be the DMR flash dryer, which is capable of producing hemi-hydrates.

Gypsum mixing

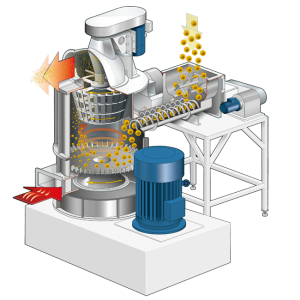

For the production of construction materials, water is mixed to the hemi-hydrate to form a di-hydrate. This reaction can be accelerated by adding a small amount of water to the powder before adding the full complement of water. The Flexomix continuous mixer is perfect for this kind of wetting or moisturizing. By bringing each particle into contact with a small amount of water, the particles become more receptive to the rest of the water that is required.

Test your product

Not convinced yet? onsider running a test first. We offer you the opportunity to test your particular process on our mixing and drying equipment at our extensive test centre in Doetinchem, the Netherlands.