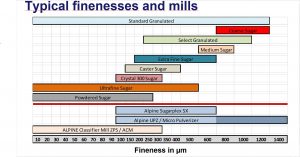

Various foods use a powder sugar which is ground granule sugar. The amount of coarse particle decides the grade of powder sugar. Generally speaking, 93.5% < 200Mesh (75 micron) are suitable size for confectionery usage. Sometime more fine powder called silk sugar is demanded. Both sugars can give a creamy frosting or icing on cakes or some pastries. But these fine powders cause problems in the manufacturing process and in use. Due to the high specific surface area, the fine powder tends to cake easily generates, absorbs moisture, and easily dust. To prevent these problems, a coarser powder sugar around 100-150 micron is still generally used. The powder sugar has following advantages.

– Good for large scale process automatic conveying

– Free-flowing

– Very fine but dust fre

Hosokawa Micron Group propose mass production processes for manufacturing fine, coarse (general size), and ultra fine powder sugars, respectively. Our sugar grinding machines are installed not only in Europe but also in also in Asia, South America and many more

SUGARPLEX

Advantages of Hosokawa Alpine Sugarplex;

- Small space requirement

- Low investment

- Low energy consumption

- Airless concept

- No duct collecting filter necessary

- No cooling necessary

- ATEX compliant pressure-shock-proof to 10 bar

- GMP-approved

- Easy to clean

- Optional additive dosing

Click here for Brochure Brochure_Sugarplex

- Grinding and classifying in one machine

- Optimum accessibility

- Finer than other classifier mills

- Easy cleaning

- Designed for processing adhesive products

- High air flow rate = cool grinding

- Excellent precision of cut, steep particle size distribution

HOSOKAWA MIKRO PULVERIZER (TYPE AP)

Advantages of Mikro Pulverizer;

- Good cost performance

- Robust

- Stable operation

- Easy to disassemble – assemble