LACTOSE AND DAIRY PRODUCTS

Tailor-made solutions for the requirements of the dairy industry

From grinding to pulverising: The production of lactose and dairy products brings with it a number of challenges. Hygienic design, very good cleanability and a low risk of contamination are just some of them.

In addition, there is a high explosion risk, so that the machines and systems need to be laid out as defined in international directives and standards to be explosion-protected. Hosokawa Alpine knows these challenges and has developed the appropriate solutions for the production of lactose and dairy products.

LACTOSE

Pulverisation down to the µm range combined with fulfilment of the highest hygiene and safety requirements.

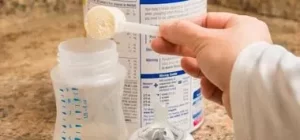

As one of its main applications in the manufacture of infant formula powder, lactose must fulfil the highest purity criteria. Systems with no dead zones which are easy to clean permit a production process that is free from reservations.

At the same time, the particle size distribution must be set as a function of the comminution so that properties such as ease of use and solubility are guaranteed.

Final applications

Infant Food

Sauces, desserts

Confectionary

Baked goods industry

Meat preparations

Alpine Fine Impact- and Classifier Mills

Tailored to suit the requirements of the dairy industry together with our customers.

- Deglomeration and pulverisation

- Precise top size

- Standard fineness values from 100 to 200 mesh and finer

- Special design for wet cleaning with no dead zones

- Combination of highly precise classifier technology and fine impact mills

MILK MINERALS

Fine solutions for the production of dairy products

The main constituent of milk minerals is calcium phosphate. It can be precipitated from the whey by adjusting the ph value and separated by means of a centrifuge. The resultant powder after drying has a high calcium content that originates from a biological souce,, namely milk.

Whey is a by-product from the manufacture of cheese, curd chesse or casein. The milk minerals are offered under different trade names by several of the larger producers in the milk processing industry.

Because the demanded fineness values range between < 7 µm and < 15 µm, it is only jet mills that can be used for grinding. Hosokawa Alpine has had great success with its fluidised bed opposed jet mill AFG for the grinding step.

Although fineness values < 15 µm can be achieved with the spiral jet mills, higher fineness values with correspondingly steeper particle size distributions are accomplished with the AFG mills.

Dairy Powder Processing Systems

Hosokawa Micron specializes in providing the best possible mechanical and hygienic designs for the dairy industry and is an expert in unusual combinations of powder processing technologies.

In contrast to the sterilization or pasteurization of milk for direct consumption, our primary focus is the handling and processing of spray-dried milk powders. Important aspects here include fast solubility, in coffee creamer for example, adaptable functionalities in applications in the feed industry, and the accurate blending of functional additives in baby food.

Our close relationship with the dairy industry and focused approach means that customers can truly rely on our expertise: a century of dedicated research and development in powder processing technologies.

The food industry is one of our key business sectors and we invested significantly in developing our technologies, expertise and services in this field. This has led to a wide range of equipment for laboratories, pilot plants and full-scale installations.

Mixing Systems for Infant Formula Powder

When designing an infant formula production line, the key element is to ensure the correct content of all components in the premix mixture and the correct ratio between premix and carrier. Meeting the stringent requirements concerning infant food premix is one of the greatest challenges in mixing technology.

The challenge is to overcome the contradiction between the very low content of active ingredients (such as vitamins, salts and mineral complexes) and the very small doses of the final product on the one side and the relatively large batches with shortest possible batch times on the other.

Furthermore the focus should be on avoiding inaccuracies in the final packing, because there are serious consequences involved. For this aspect Hosokawa Micron feels the mutual responsibility together with their customers to provide infants with the best possible baby food powder.

Expert Engineering of Baby Food Mixers

Over the years, Hosokawa Micron has supplied a great number of baby food mixers, with unusual combinations of CIP-or custom designed dry-cleaning provisions, high mixing accuracy, large volumes, low energy input and high production capacities. This requires flexibility, dedication and expert engineering.

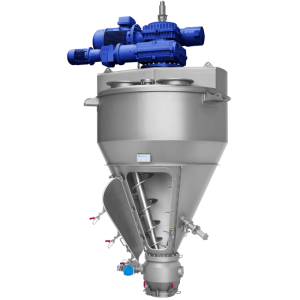

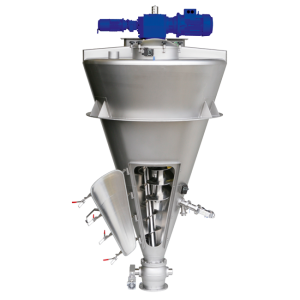

Until recently, almost all these mixers were based on traditional, proven Nauta technology, very well suitable to reach the highest possible mixing accuracies without risk of segregation and product damage. Our latest development in infant food mixing equipment focused on reducing production costs and building height which led to the introduction of the Vitomix ribbon screw mixer.

The Vitomix features even shorter batch times, better accessibility for often manual dry cleaning while maintaining the highest possible mixing accuracy. Using two conical cantilevered screws, the net energy input to the product is effectively even lower compared to the already very gentle Nauta mixer.