Whether face powder, compact powder, eye make-up of soft powder, microfine powders ensure intensive, uniform colors and are easy to apply evenly and comfortably. The manufacture of such high-grade cosmetic articles is complex. The production of powder mixtures made up of pigments, carriers, fragrance and care components is challenging because all constituents need to be uniformly micronized. The manufacture takes place under stringent statutory hygiene conditions.

Frequent product and color changes call for uncomplicated cleaning and a perfect cleaning result. Not least because of these challenges, many leading cosmetics manufacturers produce high-grade, cosmetic products in powder form using Hosokawa Micron/Alpine systems.

Mixing powders with the Cyclomix

The Cyclomix can produce face powders in homogeneous, lump-free batches by spraying continuously from its central spray nozzle and rotating at variable rotor speeds of 3 – 30 m/s, including low speeds gentle enough for mixing fragile or heat-sensitive components. The Cyclomix disperses pigments thoroughly and does not over-wet the mixture, eliminating the risk of lumps and the need for additional milling. This unique combination minimizes product losses and helps avoid downtime for cleaning.

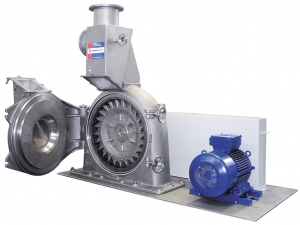

Milling and micronizing face powder

Powders form a considerable part of the base materials needed for cosmetics. The production of these powders requires milling and micronizing, which is a specialism of Hosokawa Alpine. Hosokawa Alpine has established itself as an expert in dry powder processing and supplies complete systems for the formulation of powdery cosmetics. This includes systems for fine grinding of dry raw and base materials and the micronizing of face powder.